Formworks

At this point the formworks lose their function and can be removed because the structure is now able to self-support. Formwork can be made with different materials: the most used are those made with wooden elements or with metal panels, but with greater frequency also elements based on expanded polystyrene or elements in fibro-compressed or plywood materials are used.

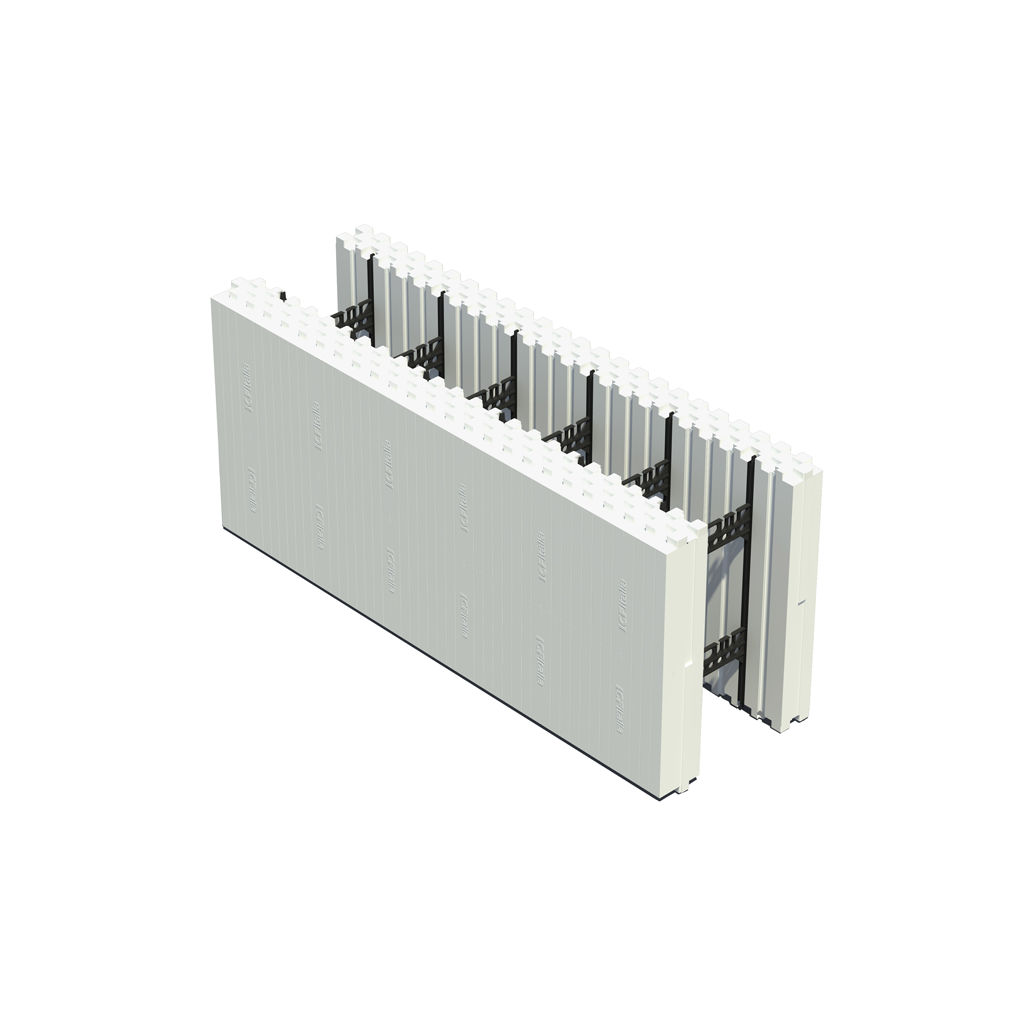

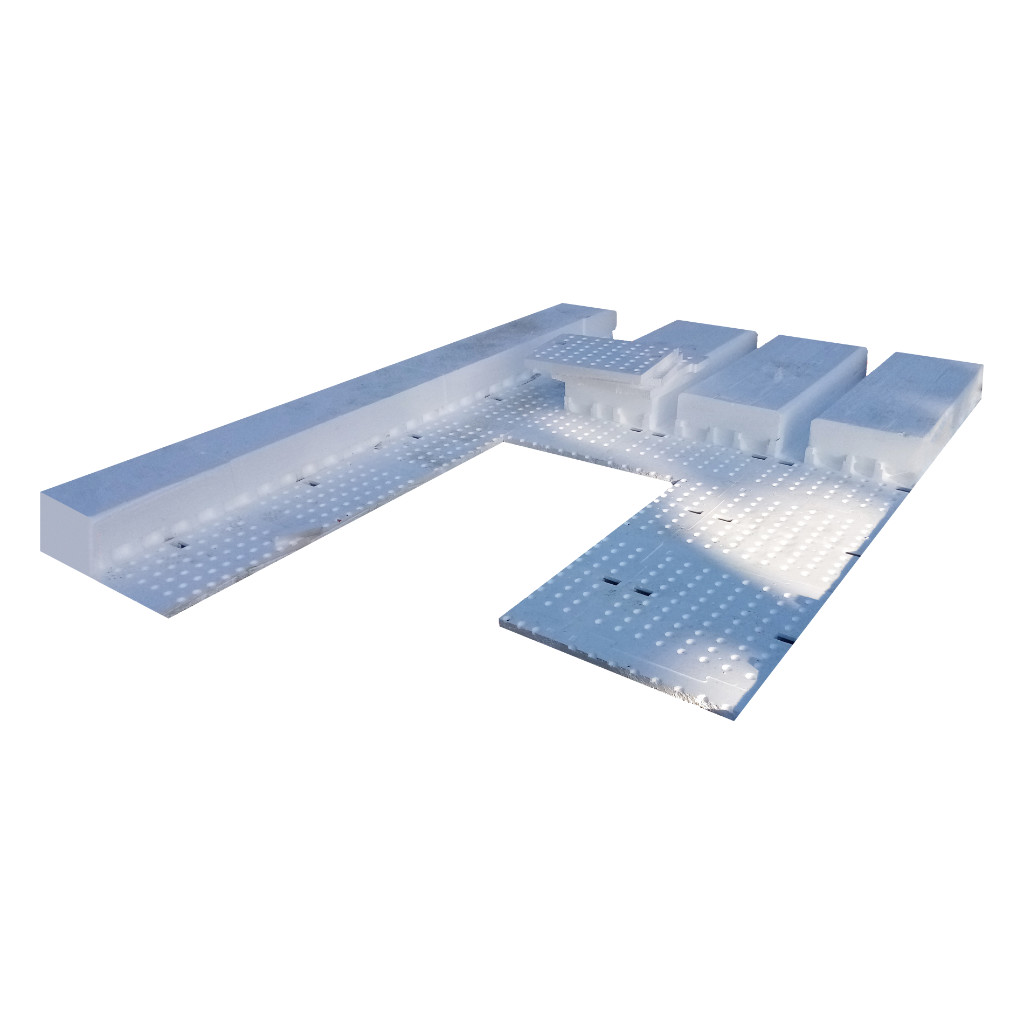

When a material is thrown into a formwork which is then not removed, remaining integral with it, we speak of disposable formwork. In this case, each formwork is used for a single casting, while traditional wooden or metal formworks are used several times. Disposable formworks are used also for the construction of crawl spaces, cavities and ventilated floors (plastic elements) as well as, in the form of panels made of heat-insulating materials (treated wood wool, polystyrene, etc.), to give the structure (wall, pillar, etc. ) a suitable thermal inertia in order to prevent the onset of thermal bridges.

The function of the formwork is twofold:

– geometric: it is made in such a way that the concrete that is casted can take the shape required by the project.

– mechanical: it must not be deformed, it must therefore be able to withstand the pressure of the jet on its walls and the action of compaction vibrations. In addition, the formwork must guarantee a watertight seal since the lack of perfect seal would cause the finer fraction of the mixture to come out with the consequent formation of a spongy structure and gravel nests.

Accessories to assemble formwork

– The spacers are formwork accessories necessary for the assembly and locking of the various panels that make up the formwork of a reinforced concrete wall. They are pre-molded elements made of metal or PVC that remain almost completely incorporated in the hardened concrete (disposable elements).

– The props are used for the construction of concrete walls. Thanks to the support shoring systems, the pressure exerted by the fresh concrete on the face of the formworks is transferred to the ground.

The typical problems of the walls made with “disposable formwork” of a traditional type are clearly visible in the images on this page, which show the high amount of wood needed, which must be subsequently removed.

On the contrary, with ICF ITALIA technology the “integrated formwork” (made of high density polystyrene) remain incorporated with the concrete casting and the site is clean, cheap and safe.